In the advanced mechanical scene, Industrial Robotics plays a vital part in improving efficiency, proficiency, and security. Understanding the basics of mechanical mechanical autonomy can altogether boost your career in computerization. This paper will investigate the key angles of mechanical mechanical technology, counting their focal points and impediments, give a nitty gritty table summarizing basic focuses, reply common questions, and conclude with the in general affect on career development.

Key Takeaways

- Industrial robots are utilized for assignments such as gathering, welding, portray, and fabric handling.

- Understanding Industrial Robotics can open up various career openings in the robotization industry.

- Learning Industrial Robotics includes acing both equipment (mechanical parts) and program (programming).

- Robotics in businesses upgrades efficiency, accuracy, and safety.

- Challenges incorporate tall introductory costs and the require for specialized skills.

Summary of Industrial Robotics Fundamentals

| Aspect | Description |

|---|---|

| Definition | Use of robots in industrial settings for various tasks |

| Key Components | Mechanical parts, sensors, controllers, and software |

| Main Applications | Assembly, welding, painting, material handling |

| Benefits | Productivity, precision, safety, cost efficiency, versatility |

| Challenges | High cost, maintenance, need for skills, job displacement, integration complexity |

| Career Opportunities | Robotics engineer, automation specialist, maintenance technician, programmer |

Understanding Mechanical Robotics

What Are Mechanical Robots?

Industrial robots are programmable machines outlined to perform a wide run of assignments in fabricating and generation situations. These assignments incorporate welding, portray, get together, fabric dealing with, and more. By robotizing these forms, mechanical robots offer assistance companies accomplish higher accuracy, speed, and consistency.

Components of Industrial Robotics

To get a handle on the Mechanical Mechanical autonomy Essentials Clarified: Boost Your Career in Robotization, it is basic to get it the key components of mechanical robots:

- Maniulaptor (Arm): The controller is the robot’s arm, which moves and positions the end-effector to perform particular tasks.

- End-Effector: This is the instrument connected to the robot’s arm, such as a gripper, welder, or shower weapon, depending on the application.

- Controller: The controller acts as the robot’s brain, handling informational and controlling its movements.

- Sensors: Sensors give the robot with data almost its environment, empowering it to perform assignments precisely and safely.

- Power Supply: The control supply gives the fundamental vitality for the robot to operate.

Applications of Industrial Robotics

Manufacturing

Manufacturing is the most common application of mechanical Industrial Robotics. Robots are utilized for get together, welding, portray, and quality control, essentially upgrading efficiency and item quality.

Automotive Industry

In the car industry, robots are utilized for assignments such as welding car bodies, gathering parts, and portray vehicles. The accuracy and productivity of robots guarantee high-quality generation and decreased labor costs.

Electronics

The gadgets industry utilizes robots for gathering circuit sheets, testing components, and bundling wrapped up items. Robots can handle fragile components with tall exactness, diminishing the hazard of damage.

Healthcare

Robotics in healthcare incorporates surgical robots, which help specialists in performing complex methods with more noteworthy exactness. Robots moreover handle errands such as pharmaceutical apportioning and research facility automation.

Food and Beverage

In the nourishment and refreshment industry, robots are utilized for bundling, sorting, and palletizing items. They guarantee cleanliness and consistency in dealing with nourishment items.

Benefits of Industrial Robotics

Increased Productivity

One of the essential benefits of mechanical Industrial Robotics is expanded efficiency. Robots can work 24/7 without breaks, driving to higher generation rates and quicker turnaround times.

Enhanced Precision

Robots perform errands with a tall degree of precision and repeatability. This accuracy diminishes blunders and guarantees reliable item quality, which is significant in businesses like gadgets and car manufacturing.

Improved Safety

By taking over unsafe and monotonous assignments, robots diminish the chance of work environment wounds. This leads to a more secure working environment for human laborers, who can center on more complex and less perilous tasks.

Cost Efficiency

While the introductory venture in mechanical robots can be tall, they offer long-term taken a toll reserve funds. Robots decrease labor costs, minimize squander, and increment productivity, driving to by and large taken a toll reductions.

Versatility

Modern mechanical robots are exceedingly flexible and can be modified to perform different assignments. This versatility makes them important resources in businesses with differing generation needs.

Challenges of Industrial Robotics

High Starting Investment

The fetched of acquiring and introducing mechanical robots can be considerable. Little and medium-sized ventures (SMEs) may discover it challenging to bear this introductory investment.

Maintenance and Repair

Robots require customary upkeep to guarantee ideal execution. Upkeep and repair costs can include up, particularly if specialized specialists are needed.

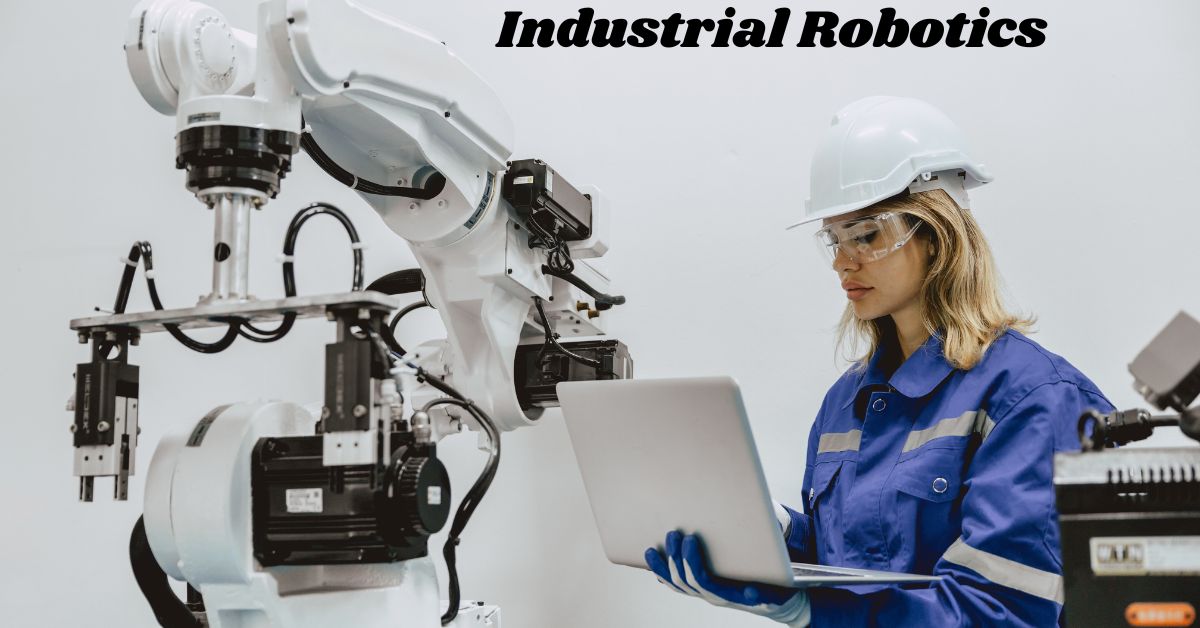

Specialized Abilities Required

Operating and programming Industrial Robotics request specialized information and abilities. Companies require to contribute in preparing their workforce or contract gifted professionals.

Job Displacement

The mechanization of errands by robots can lead to work uprooting in certain divisions. Whereas robots make modern work openings, they moreover supplant a few manual labor positions.

Integration Complexity

Integrating robots into existing generation frameworks can be complex and time-consuming. Legitimate arranging and execution are fundamental to guarantee consistent integration.

Career Openings in Industrial Robotics

Robotics Engineer

Industrial Robotics engineers plan, construct, and keep up mechanical robots. They work on making strides robot execution, creating modern applications, and guaranteeing the security and productivity of mechanical systems.

Automation Specialist

Automation pros center on joining robots into fabricating forms. They plan and execute computerization arrangements to optimize generation and move forward efficiency.

Maintenance Technician

Maintenance professionals are capable for the upkeep of mechanical robots. They perform standard support, troubleshoot issues, and carry out repairs to keep robots working smoothly.

Robotics Programmer

Robotics software engineers create and actualize program programs that control mechanical robots. They type in code, test programs, and guarantee that robots perform errands precisely and efficiently.

Research and Development

Professionals in inquire about and improvement (R&D) work on progressing mechanical technology innovation. They investigate unused applications, create imaginative arrangements, and thrust the boundaries of what robots can achieve.

Key Concepts in Industrial Robotics

Kinematics and Dynamics

Understanding the development of robots includes kinematics (ponder of movement) and flow (ponder of powers). Authority of these concepts is pivotal for planning and controlling robots.

Robot Programming

Robot programming includes composing code to control the robot’s developments and activities. Common programming dialects incorporate Python, C++, and restrictive dialects particular to robot manufacturers.

Sensors and Perception

Sensors empower robots to see their environment and make educated choices. Vision sensors, material sensors, and vicinity sensors are commonly utilized in mechanical robotics.

Human-Robot Interaction (HRI)

HRI centers on the interaction between people and robots. Planning natural and secure interfacing for human administrators to control and collaborate with robots is a key zone of research.

Artificial Insights (AI) and Machine Learning

AI and machine learning empower robots to learn from information and make strides their execution over time. These innovations are necessarily to creating more brilliantly and independent robots.

Future Patterns in Industrial Robotics

Collaborative Robots (Cobots)

Cobots are outlined to work nearby people, upgrading efficiency and security. They are prepared with progressed sensors and security highlights to guarantee secure collaboration.

Auto Mobile Robots (AMRs)

AMRs can explore and perform errands independently in energetic situations. They are utilized in coordinations, warehousing, and fabricating to transport materials and goods.

Advanced AI and Machine Learning

Advancements in AI and machine learning are making robots more brilliant and more competent. Robots can presently learn from information, adjust to modern errands, and make choices based on real-time information.

5G Connectivity

5G innovation empowers quicker and more solid communication between robots and control frameworks. This network improves the execution and responsiveness of mechanical robots.

Internet of Things (IoT)

The integration of IoT in mechanical mechanical technology permits robots to communicate with other gadgets and frameworks. This network empowers real-time checking and information investigation for made strides efficiency.

How to Get Begun in Industrial Robotics

Education and Training

A solid instructive foundation in building, computer science, or a related field is fundamental. Numerous colleges and specialized establishing offer specialized programs in mechanical autonomy and automation.

Online Courses and Certifications

Online courses and certifications give a adaptable way to pick up information and aptitudes in mechanical mechanical technology. Stages like Coursera, edX, and Udacity offer courses on mechanical autonomy essentials, programming, and AI.

Hands-On Experience

Practical involvement is vital for acing mechanical mechanical autonomy. Internships, co-op programs, and hands-on ventures give profitable openings to apply hypothetical knowledge.

Networking

Building a proficient arrange in the mechanical autonomy industry can open entryways to work openings and collaborations. Go to industry conferences, connect proficient organizations, and interface with specialists in the field.

Staying Updated

The field of mechanical mechanical technology is always advancing. Remain overhauled with the most recent patterns, advances, and inquire about by perusing industry distributions, going to webinars, and taking an interest in online forums.

FAQ’s (Industrial Robotics Fundamentals)

What is an Industrial robot?

An mechanical robot is a programmable mechanical gadget utilized in fabricating and generation situations to perform assignments such as get together, welding, and portray with tall exactness and efficiency.

What aptitudes are required to work with Industrial Robotics?

Key aptitudes incorporate information of mechanical designing, programming, gadgets, and an understanding of mechanization forms. Recognition with mechanical autonomy program and upkeep procedures is too essential.

How do mechanical robots move forward safety?

Industrial robots can handle perilous errands, such as dealing with overwhelming loads or working in extraordinary temperatures, lessening the hazard of damage to human workers.

What are the fundamental sorts of Industrial Robotics?

Common sorts incorporate verbalized robots, SCARA robots, delta robots, and Cartesian robots, each suited for distinctive applications and errands in the industry.

What are the future prospects of a career in Industrial Robotics?

The request for talented experts in mechanical mechanical technology is anticipated to develop as more businesses embrace robotization advances, advertising promising career prospects and openings for advancement.

Conclusion

Industrial Robotics is a quickly advancing field with noteworthy potential to improve efficiency, accuracy, and security in different businesses. Understanding the essentials of Industrial Robotics technology and picking up important aptitudes can give a considerable boost to your career in mechanization. Whereas there are challenges such as tall starting costs and the require for specialized preparing, the benefits of expanded productivity, taken a toll investment funds, and moved forward security make it a beneficial venture. As mechanization proceeds to grow, the request for gifted mechanical autonomy experts will as it were increment, making presently an great time to seek after a career in this energizing field.

By acing the essentials of Industrial Robotics and remaining upgraded with the most recent headways, you can position yourself at the cutting edge of the mechanization insurgency, opening up various openings for career development and improvement.